Tips For Growing Bigger Peaches At Home: From The Experts

Expert advice from the horticultural team at Action Home Services Want bigger, juicier peaches from your backyard tree? This expert guide from Action Home Services walks homeowners through the science and art of growing large, high-quality peaches in Ontario. From choosing the right variety and understanding fruit growth stages to mastering irrigation, thinning, pruning, and […]

How to Windproof Your Outdoor Space, Including Pergolas & Gazebos

If you’re tired of the wind limiting how and when you use your outdoor space, building glass-enclosed pergolas or gazebos is the game-changer you need. At AHS, we help homeowners across Toronto and the GTA create functional, stylish, and windproof backyards using smart design strategies – from anchoring structures properly to adding natural windbreaks and […]

AHS Partners with Lumon Canada To Offer Glass Enclosures For Patios, Porches, Balconies & More!

Action Home Services is thrilled to announce an exciting new partnership with Lumon! Bringing you even more incredible ways to transform your outdoor spaces, expand your living areas, and enjoy your home like never before, no matter the season! Think year-round comfort, amazing style, and a ton more usable space – no matter what the […]

What Is the Most Expensive Part of Building a Pool?

Building a pool can be a significant investment, and understanding where the majority of the costs come from can help you plan your project effectively. While there are several factors that influence the overall expense, the most expensive part of building a pool often comes down to materials, labor, and additional features. 1. Excavation and […]

Guidelines for Transitioning Between Hot Tubs and Cold Plunges

Transitioning between hot tubs and cold plunges, often referred to as contrast therapy or hot-cold immersion, can provide various health benefits, such as improved circulation, muscle recovery, and stress relief. However, it’s important to approach these transitions with caution to avoid potential health risks. General Guidelines Check with a Healthcare Professional: Before incorporating contrast therapy […]

Beginner’s Bliss: 5 Low-Maintenance Plants for Ontario Gardeners

For novice gardeners venturing into the green realm of Ontario, selecting low-maintenance plants can set the foundation for a flourishing garden with minimal effort. Top 5 Resilient and Easy-Care Plants for Ontario’s Climate 1. Hostas (Hosta spp.): Hostas are the epitome of effortless elegance in Ontario gardens. With their lush foliage and shade-loving nature, these […]

Grass Cutting: Facts About Aeration and Dethatching

Having your lawn look green and healthy isn’t just mowing it regularly. There are several key lawn maintenance practices you’ll want to keep in mind if you really want a strong, healthy lawn, with them being aeration and dethatching. These two processes are the most responsible for your lawn growing well and healthy. Aeration is […]

Why Sealcoating Your Driveway Can Increase Property Value

Sealcoating your driveway is more than just a protective measure, but a simple, cost-effective way of adding value to your home. Freshly sealing your driveway enhances curb appeal, extends the lifespan of the asphalt, and protects it from weather damage and wear. It shows potential buyers that your home is well-maintained, giving them confidence that […]

Top 10 Easy-To-Grow Dog Safe Perennials

In our evergreen pursuit of creating safe and harmonious spaces for our four-legged companions, this article explores the enchanting world of dog-friendly perennials. Delving into a garden adorned with vibrant colours and lush foliage, we embark on a journey to discover 20 perennials that not only add aesthetic charm to your outdoor haven but also […]

DIY Methods To Remove Weeds From Interlocking Brick Driveways

When it comes to landscaping, many people agree that interlocking brick driveways are aesthetically pleasing options for driveways, and are usually easy to maintain as well. This explains their popularity in many parts of the country. One of the common problems people encounter with these driveways is dealing with weeds. These usually grow between the […]

Why Does My Asphalt Driveway Crack?

Asphalt driveway cracks are infuriating, but nearly can’t be avoided in the long term. The major culprits are the changing weather, water, and age. Asphalt melts and expands when hot in the summer and is cold and tight in the winter, so it softens and cracks. Water makes the situation worse by seeping in and […]

What Is the Ideal Depth for Your Pool?

When planning your dream pool, one of the most important decisions you’ll make is its depth. While it might not seem like the most exciting choice, getting the depth just right is key to ensuring your pool is as fun, functional, and safe as possible. The depth you choose will influence how the pool is […]

Fun Facts About Polymeric Sand for Homeowners

When it comes to creating beautiful and long-lasting outdoor spaces, every detail matters. One often overlooked yet critical component of hardscaping is polymeric sand. This innovative material not only enhances the appearance of patios, driveways, and walkways but also ensures they stay durable and low-maintenance for years. At Action Home Services, we’re here to break […]

How to Choose the Right Irrigation System for Your Residential Landscape

A well-chosen irrigation system can simplify the task of maintaining a lush, healthy landscape while conserving water and keeping costs under control. However, selecting the best system for your residential yard requires understanding your specific needs, water availability, and landscape layout. Here’s how you can make an informed decision. 1. Understand Your Landscape’s Water Needs […]

How Slippery Are Interlocking Pavers in Winter and Rain?

Interlocking pavers are a popular choice for driveways, patios, and walkways because of their durability, aesthetics, and functionality. However, a common concern for homeowners is whether these surfaces become slippery during rain or icy winter conditions. Here’s what you need to know to make an informed decision. Interlocking Pavers and Rain Interlocking pavers are generally […]

How to Choose Polymeric Sand Colors for Your Landscape Project

When it comes to creating a polished and cohesive look for your outdoor space, polymeric sand plays a surprisingly important role. As homeowners, you may find yourselves focusing on the big-picture elements—pavers, plants, or patio furniture—but the details, like the color of your polymeric sand, can make all the difference. At Action Home Services, we’ve […]

Can I Turn My Polymeric Sand to Permeable?

As a homeowner, you might have come across polymeric sand if you’ve ever installed or maintained a patio, driveway, or walkway made of pavers. This special sand is popular for locking pavers in place and keeping weeds at bay. But if you’re looking to make your outdoor spaces more eco-friendly and water-efficient, you might be […]

Finding Your Perfect Landscaper: A Fun Guide to Digging Up the Best

So, you’ve decided it’s time to spruce up your outdoor space. Whether you’re dreaming of a sleek patio, a luscious garden, or a jaw-dropping pool, the key to turning that Pinterest board into reality is finding a trusted landscaper. But where do you start? Grab your shovel—we’re digging into the best ways to uncover the […]

Making a Splash: Indoor vs. Outdoor Pools for Your Home

When considering a swimming pool for your home, deciding between an indoor pool and an outdoor pool can be challenging. Both options have unique advantages and drawbacks, catering to different lifestyles, budgets, and preferences. This guide combines their differences, pros, and cons to help you make the right choice. Pros and Cons of Indoor Pools […]

How to Clean Asphalt Sealant Off The Curb

Have you recently sealed your driveway and accidentally sprayed too much sealant on your curbs? It’s frustrating, and it can also be an eyesore for you and other drivers. One small mistake can stand out like a sore thumb on your driveway. But, you can always clean sealant off curbs without panic! Let’s walk through […]

Do I Need to Waterproof My Deck and What Are the Benefits?

Ah, the deck. It’s your summer sanctuary, the stage for epic barbecues, quiet morning coffees, and late-night stargazing. But have you ever stopped to wonder if your deck is crying out for a little TLC? Specifically, does it need waterproofing? Let’s dive into why waterproofing your deck isn’t just a smart choice—it’s practically a no-brainer! […]

How to Know if Your Backyard Can Fit a Pool?

Dreaming of turning your backyard into a summer oasis with a sparkling pool? Whether it’s for cannonball contests, serene evening swims, or just lounging by the water, a pool is a dream worth exploring. But first, you’ll need to figure out if your backyard is ready to take the plunge. Here’s how to find out […]

What Is The Difference Between Hardscaping And Landscaping?

If you’ve ever dreamed of transforming your backyard into an outdoor paradise, you’ve likely come across the terms hardscaping and landscaping. While they might sound similar, they refer to two distinct aspects of outdoor design. Understanding the difference—and how they work together—is key to creating a balanced, functional, and beautiful space. Hardscaping: The Backbone of […]

What is the Smallest Pool You Can Build? A Guide to Compact Pools

If you’ve always dreamed of having a pool but feel your backyard might be too small, there’s good news: compact pools, often called “plunge pools,” are an excellent solution for limited spaces. Here’s what you need to know about building the smallest pool possible. 1. What Is a Plunge Pool? A plunge pool is a […]

Are Heated Driveways Expensive? Understanding the Costs Involved

Heated driveways offer a luxurious and practical solution to winter’s harsh conditions, eliminating the need for shoveling or snowblowing. However, many homeowners wonder if the convenience comes with a hefty price tag. Let’s take a closer look at the costs involved in installing and operating a heated driveway to determine if it’s worth the investment. […]

Glycol vs. Electric Heated Driveway: Which is Right for You?

When considering a heated driveway, homeowners often find themselves weighing the pros and cons of glycol (hydronic) systems versus electric heated driveways. Both options provide effective snow and ice melting, but they operate differently and have distinct advantages. Here’s a breakdown to help you choose the best option for your needs. Glycol (Hydronic) Heated Driveways […]

Questions to Ask Before Hiring a Pool Contractor

Adding a pool to your property is an exciting decision that can enhance your outdoor living space and provide endless enjoyment for years to come. However, choosing the right contractor is just as important as selecting the pool design. A skilled and reliable contractor can turn your vision into reality, while a poorly chosen one […]

When Is the Best Time of Year to Install a Pool?

Deciding when to install a pool can impact not only your project’s timeline but also the cost and overall experience of the installation process. Choosing the right time of year ensures that you get the most out of your investment. Here’s a look at the best time to install a pool and why. 1. Early […]

What Is Asphalt Sealant Made Of?

Asphalt sealant plays a key role in preserving and protecting paved surfaces. Whether it’s a driveway, a parking lot, or a small private road, this dark, smooth coating is more than just for looks. It helps defend against harsh weather, water damage, UV rays, and chemicals that can wear down asphalt over time. But what […]

What Materials Are Commonly Used for Building Fire Pits?

Fire pits are a fantastic way to add warmth and ambiance to your outdoor space, making them a favorite feature for many landscape designs. Whether you’re roasting marshmallows or enjoying a cozy evening, choosing the right materials for your fire pit is essential for both safety and durability. Here are some commonly used materials and […]

Top 10 Coolest Items to Include in Your Outdoor Kitchen to Make It Unique

Creating a one-of-a-kind outdoor kitchen is about more than just functionality; it’s about designing a space that makes a statement and enhances your outdoor dining experience. Whether you’re hosting a barbecue with friends or enjoying a peaceful meal under the stars, the right tools and features can elevate your outdoor cooking area into something special. […]

Elevate Your Playtime: The Ultimate Backyard Sports Courts

If you’ve ever dreamed of turning your backyard into an athletic oasis, sports courts are the perfect way to make that dream a reality. Not only do they provide a great place for physical activity, but they also offer a space for family and friends to bond over games and competitions. Discover Sports for Backyard […]

Light Up Your Life: 7 Outdoor Lighting Ideas to Transform Your Yard

When it comes to creating a warm, inviting, and safe outdoor environment, landscape lighting plays an essential role. Beyond the practical benefits of safety and security, outdoor lights add aesthetic charm, accentuating the beauty of your backyard or front yard. With thoughtful placement, landscape lighting can transform your outdoor space into a nighttime oasis, highlight […]

Is Building a Pool a Good Investment?

Building a pool can be an exciting upgrade that adds luxury and relaxation to your home. However, homeowners often wonder if a pool is a worthwhile financial investment. While pools offer lifestyle benefits, the return on investment (ROI) depends on several factors, including property location, maintenance costs, and buyer preferences. Here’s a closer look at […]

How Can I Tell If My Pool Is Leaking? Key Signs to Watch For

A pool leak can lead to costly water loss, damage to your landscaping, and increased utility bills if left undetected. While some water loss due to evaporation is normal, a persistent or unexplained drop in water levels may indicate a leak. Here are key signs and simple methods to help you determine if your pool […]

How Pool Liners Are Installed?

Pool liners are essential for vinyl pools, acting as a waterproof layer that protects the structure while giving the pool its final appearance. Installing a new pool liner—or replacing an old one—requires precision to ensure a smooth, wrinkle-free fit. The Must-Know Steps for Installing Your Pool Liner Here’s an overview of the pool liner installation […]

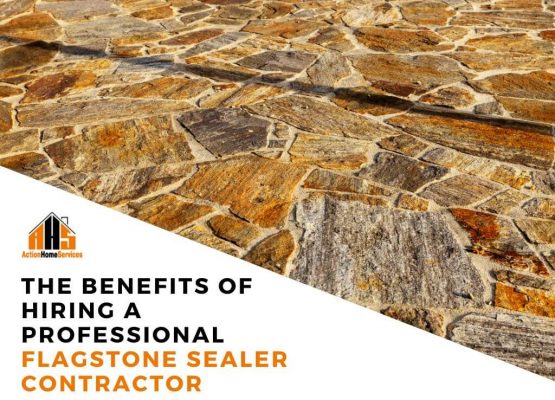

The Benefits of Hiring a Professional Flagstone Sealer Contractor

Flagstone patios, walkways, and driveways are elegant additions to any property, offering a natural and timeless aesthetic. However, over time, weather elements, foot traffic, and exposure to moisture can cause flagstone surfaces to fade, stain, or become brittle. To maintain their beauty and durability, applying a high-quality sealant is essential—and that’s where hiring a professional […]

Things to Know When Building a Pool: A Guide for Homeowners

Building a pool is an exciting project that can transform your backyard into a personal oasis. However, it requires careful planning and consideration to ensure the investment brings lasting enjoyment. Here are some essential things to know before diving into the pool-building process. 1. Budget Planning The cost of building a pool can vary significantly […]

Designing a Pool in a Sloped Backyard: Key Considerations

Building a pool in a sloped backyard may seem like a challenge, but with the right design approach, it can become a unique and stunning feature of your outdoor space. Incorporating a pool into a sloped yard not only maximizes your landscape’s potential but also allows for creative solutions that add character to your property. […]

The Best Polymeric Sand on the Market: Romex

When it comes to keeping your interlock patio looking pristine and weed-free, choosing the right polymeric sand is essential. Polymeric sand fills the gaps between pavers, preventing weeds, insects, and water damage. Among the many options available, Romex stands out as one of the best polymeric sands on the market. Here’s why Romex is a […]

What to Avoid: DIY Driveway Maintenance

So, you want to DIY your driveway maintenance. It extends your driveway’s health and keeps it fresh for any season. But if you’re not careful, you might ruin your driveway. Let’s get into things to avoid when it comes to DIY driveway maintenance. 1. Skipping the Cleaning Step Dirt may seem harmless here. But the […]

Do I Need a Permit to Build a Pool in Ontario?

If you’re planning to build a pool in Ontario, one of the first questions you might ask is, “Do I need a permit?” The answer is generally yes, as a permit ensures that your pool meets safety standards and complies with local regulations. 1. Pool Enclosure Permit In Ontario, a pool enclosure permit is mandatory […]

Things to Consider When Installing a Pool

Installing a pool can be an exciting home improvement project, transforming your backyard into a relaxing oasis. However, there are several crucial factors to consider to ensure a successful installation and long-term enjoyment. Essential Considerations for a Successful Pool Installation Here’s a guide to help you navigate the decision-making process. 1. Budget and Costs Before […]

How to Choose a Licensed Pool Contractor: Key Tips for Homeowners

Choosing the right licensed pool contractor is crucial when planning to build a pool. A well-designed pool can transform your outdoor space, but a poor contractor can lead to delays, unexpected costs, and unsatisfactory results. Here are some essential tips to help you choose the right pool contractor for your project. 1. Verify Licensing and […]

The Cost to Operate a Heated Driveway in Ontario: What You Need to Know

Ontario winters can be tough, and keeping a driveway clear of snow and ice can be a time-consuming task. A heated driveway is an attractive solution, but what does it cost to operate in Ontario? Let’s break down the factors that determine the cost of running a heated driveway system in this region. Key Factors […]

What Does It Cost to Build a Heated Driveway?

As winters become more severe, many homeowners are turning to heated driveways to avoid the hassle of snow removal. But what does it actually cost to install one? Let’s break it down. Installation Costs The cost of building a heated driveway depends on factors like the size of your driveway, the type of heating system, […]

How to Improve Drainage Around Your Pool Patio?

Proper drainage around your pool patio is essential to keep the area safe, dry, and free from water damage. Poor drainage can lead to standing water, slippery surfaces, and erosion of the patio material. Fortunately, there are several ways to enhance drainage around your pool patio, and one of the best solutions involves using Romex […]

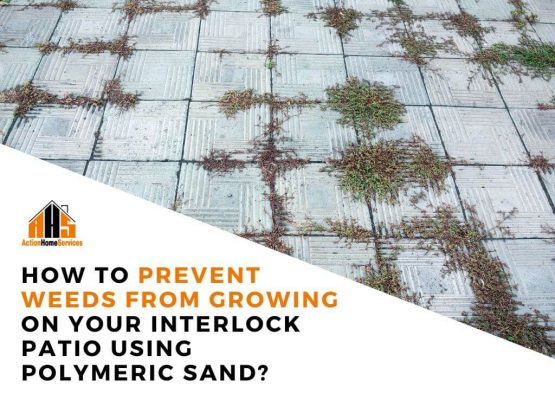

How to Prevent Weeds from Growing on Your Interlock Patio Using Polymeric Sand?

An interlock patio adds beauty and function to your outdoor space, but keeping it free of weeds can be a challenge. Weeds often sprout between the pavers, diminishing the clean look of your patio. Fortunately, using polymeric sand is an effective way to prevent weeds from growing on your interlock patio. Here’s how it works […]

How to Choose Heated Driveway Installation Services?

Investing in a heated driveway is a smart way to make winter maintenance more manageable and safe. However, selecting the right company for your heated driveway installation is critical to ensure quality and longevity. Tips for Picking the Best Heated Driveway Installation Services Here’s how to choose the best heated driveway installation services for your […]

How Does Weather Affect My Asphalt?

As the weather gets warmer, you might’ve noticed some cracks or uneven spots on your asphalt driveway. Don’t worry, it’s not you. A lot of that damage doesn’t come from how often you drive on it, it actually comes from the weather. The weather’s effect on asphalt is something many homeowners don’t think about until […]

The Different Types of Heated Driveways: Which Is Right for You?

As winter approaches, many homeowners dread the thought of shoveling snow from their driveways. Heated driveways offer a practical solution, providing safety and convenience by automatically melting snow and ice. If you’re considering this upgrade, it’s important to understand the different types of heated driveway systems available. Here’s a breakdown to help you decide which […]

Everything You Need to Know About Auto Covers for Pools

Auto covers have become an essential feature for many pool owners, offering a combination of safety, convenience, and energy efficiency. If you’re considering investing in one, here’s a breakdown of everything you need to know about auto covers and why they’re a great addition to your pool. 1. What is an Auto Cover? An auto […]

How to Extend Your Pool Season?

As the weather cools, pool owners don’t have to close their pools right away. With the right tools and techniques, you can extend your pool season into fall and even early winter. One of the most effective ways to do this is by incorporating a motorized auto cover, which offers not only convenience but also […]

How to Use Your Pool in the Winter: Maximize Comfort and Safety with a Motorized Auto Cover

Just because the temperature drops doesn’t mean your pool has to be off-limits. With the right preparations, you can enjoy your pool year-round—even during the winter months. Here’s how to safely and comfortably use your pool in the colder season, while leveraging a motorized auto cover to maximize convenience and protection. 1. Install a Pool […]

How to Winterize Your Pool?

As the weather cools and pool season comes to an end, it’s important to properly winterize your swimming pool to protect it from damage during the colder months. Winterizing your pool not only helps maintain water quality but also ensures your pool system stays in good condition. Step-by-Step Instructions Here’s a step-by-step guide to winterizing […]

How to Protect Kids Around Swimming Pools: The Importance of a Motorized Auto Cover

Swimming pools provide endless fun and relaxation, but they also come with safety concerns—especially for families with young children. Ensuring pool safety is essential, and one of the most effective ways to protect kids around the pool is by using a motorized auto cover. Keep Kids Safe and Your Pool Clean A motorized auto cover […]

Why Cracks in Wood Posts are Acceptable in Decks and Fences?

Wood is a natural material, and cracks in wood posts, often referred to as “checking,” are a common occurrence in both decks and fences. While they may seem concerning at first, these cracks are typically not structural issues and are a normal part of the wood’s aging process. The Science Behind Wood Cracking: Temperature, Humidity, […]

Finding the Best Pool Leak Repair Services Near You: A Comprehensive Guide

Experiencing a pool leak can be stressful, especially when you’re unsure of how to fix it or where to find reliable help. If you’re searching for “pool leak repair services near me,” this guide will help you navigate the process and find the best professionals for the job. 1. Identify the Problem Before reaching out […]

Essential Tips for Repairing Leaks in Pool PVC Pipes

When you’re maintaining a swimming pool, dealing with leaks in PVC pipes can be a daunting task. Fortunately, with the right tools and techniques, you can handle this common issue effectively. How to Repair Pool PVC Pipe Leaks Here’s a step-by-step guide to help you repair pool PVC pipe leaks and ensure your pool stays […]

Effective Solutions for Vinyl Pool Leak Repair

Vinyl pools are popular for their affordability and aesthetic appeal, but like any pool, they can develop leaks over time. Identifying and repairing these leaks promptly is crucial to maintaining pool water levels and avoiding costly damage. Here’s a guide to help you tackle vinyl pool leak repairs effectively. 1. Spotting the Leak: Signs and […]

A Complete Guide to Pool Liner Repairs: Fixing Common Issues

A well-maintained pool liner is crucial for keeping your pool’s structure intact and its water contained. Over time, however, wear and tear can lead to damage that requires prompt repair. Understanding common pool liner issues and how to address them can help you extend the lifespan of your liner and keep your pool in top […]

Troubleshooting and Fixing a Leaking Pool Pump

A leaking pool pump can disrupt your pool’s operation and lead to increased water bills and potential damage if not addressed promptly. Identifying and fixing the source of the leak is essential for maintaining the efficiency and longevity of your pool system. Here’s a guide to help you troubleshoot and resolve a leaking pool pump. […]

Essential Tips for Finding and Fixing a Leak in Your Inground Pool

Detecting a leak in your inground pool can be challenging, but identifying and addressing the issue promptly is vital for preserving your pool’s integrity and preventing costly repairs. Here’s a step-by-step guide to help you find and fix a leak in your inground pool. Step 1: Inspect Visible Areas Start by examining the pool’s surface […]

Essential Tips for Effective Underwater Pool Repair

Maintaining the pristine condition of your pool is crucial for ensuring its longevity and safety. When minor issues arise, such as leaks or cracks, they often require underwater repair. Here’s a concise guide to help you navigate the essentials of underwater pool repair. Your Underwater Pool Repair Guide 1. Understanding Underwater Pool Repairs Underwater pool […]

Effective Strategies for Underwater Fiberglass Pool Repair

Maintaining a fiberglass pool is crucial for ensuring its longevity and keeping it looking pristine. One common issue that pool owners might face is the need for underwater repairs. Unlike concrete or vinyl pools, fiberglass pools have unique needs when it comes to fixing leaks or cracks beneath the water’s surface. Addressing these issues promptly […]

Choosing the Best Sealant Type for Your Asphalt

Selecting the right sealant for your driveway is more than just grabbing whatever is on the shelf. There are a couple of different types, and each has advantages and disadvantages. Oil-based sealants offer long-lasting protection, especially for driveways in good condition, while water-based ones are more affordable but less durable. Rubberized sealants are great for […]

Why You Shouldn’t Ignore Leaking Pool Equipment: Address the Issue Before It Becomes a Bigger Problem

Leaking pool equipment is more than just an inconvenience; it’s a signal that your pool equipment needs attention. Many pool owners might think that a small leak is harmless, but in reality, it can lead to much larger issues if not addressed promptly. Here’s why you should pay attention to that drip and what you […]

Say Goodbye to Interlock Weeds: A Comprehensive Guide to Prevention and Removal

Are unsightly weeds wreaking havoc on your perfectly laid interlock? Don’t fret; we’ve got you covered. In this blog post, we’ll delve into effective methods for removing interlock weeds and preventing their return. From the initial power wash to the application of premium polymeric sand, we’ll equip you with the knowledge to reclaim your outdoor […]

Unlocking the Magic of Pressure Washing: Enhance Your Space with Ease

In the quest to maintain the pristine appearance of our homes and outdoor spaces, pressure washing emerges as a superhero in the realm of cleaning solutions. But what exactly is pressure washing, why is it indispensable, and how does it stack up against its counterpart, power washing? Let’s embark on a journey to explore the […]

Transforming Your Backyard into Your Own Kid-Friendly Disneyland

Who wouldn’t love to step out into their backyard and feel like they’ve entered the magical world of Disneyland? Picture the joy and wonderment of having a space that stimulates all your senses, invites playful exploration, and offers endless opportunities for fun and relaxation, especially for the little ones. With a bit of creativity and […]

Striking the Perfect Balance: Hardscape Interlocking vs. Garden Space

In the realm of landscape design, finding the ideal balance between hardscape interlocking and garden space is akin to mastering a delicate dance between structure and nature. Both elements play crucial roles in shaping outdoor environments, offering distinct benefits and aesthetic appeal. So, let’s explore how to achieve harmony between the solidity of hardscape interlocking […]

The Great Landscape DIY Adventure: Can I Do Landscaping Myself?

So, you’re standing in your backyard, staring at the uninspiring patch of grass and thinking, “Could this be better?” Perhaps you’ve envisioned a lush garden oasis or a cozy outdoor retreat. You’ve heard about landscaping, but you wonder, “Can I do landscaping myself?” The short answer is, absolutely! Embarking on a DIY landscaping project can […]

Putting Green Pleasures: 5 Ways Mini Golf Adds Joy to Every Family – Including Furry Friends!

In today’s fast-paced world, where screens dominate our attention and individual pursuits often take precedence over shared experiences, finding activities that bring families together can be a challenge. However, amidst the hustle and bustle of modern life, there exists a timeless pastime that transcends generations, ignites laughter, and fosters unforgettable memories: mini golf. But we’re […]

How Does Temperature Affect the Sealcoating Process?

Temperature affects the sealcoating and how well it works, a lot more than you think. Whether it’s too hot or too cold, the weather can seriously impact how the sealant bonds to your asphalt and how quickly it dries. The best time to book professional driveway sealing is when the temperature outside is between 15°C and […]

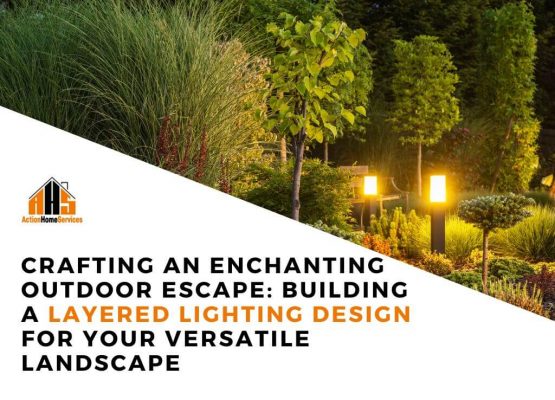

Crafting an Enchanting Outdoor Escape: Building a Layered Lighting Design for Your Versatile Landscape

As the daylight fades and shadows deepen, your garden holds the potential to become a captivating haven under the right illumination. Crafting a thoughtful lighting design not only enhances the aesthetics of your outdoor space but also amplifies its functionality, making it a safe and inviting retreat for both relaxation and entertainment. Unveiling the Essence […]

Cracking the Code of Building Permits: Your Adventure with Minor Variances

Embarking on a construction project is akin to setting sail on a thrilling adventure, filled with anticipation and the promise of realizing your dreams. But just like any voyage, there are obstacles along the way, and one of the trickiest hurdles is securing your building permit. Picture this: you’re all set to bring your dream […]

Unveiling the Power of Ontario One Call Locates: Safeguarding Ontario’s Underground Infrastructure

As you traverse your neighborhood, you might catch sight of vibrant flags and meticulously painted lines gracing a neighbor’s yard. Curiosity piques: what do these colorful markings signify? Fear not! Today, we delve into the intricate realm of Ontario One Call Locates, shedding light on the indispensable role they play in preserving the integrity of […]

Navigating Municipal Permits: A Comprehensive Guide to Streamlining Your Application Process

In the realm of home improvement projects, the mere mention of building permits often elicits a spectrum of emotions from homeowners. Some view them as burdensome obstacles standing in the way of their renovation dreams, while others see them as invaluable safeguards protecting property value and ensuring safety. This article delves into the age-old debate […]

Grilled Peaches

Grilled Peaches Vegetable oil (for grilling) 4 Ripe Peaches, halved and pitted 2 Tbsp. butter 2 Tbsp. Brown Sugar Vanilla Ice Cream, for serving Honey, for drizzling – optional Flaky Sea Salt What you’ll need Tongs or spatula Serving tray Bowl Silicone pastry brush Preparation Step 1 Heat grill to medium high Step 2 Mix […]

Elevate Your Outdoor Space: Tips for Adding a Fire Pit

Throughout history, fire pits have served as focal points for gatherings, providing warmth and companionship. In contemporary times, the fire pit has evolved into a versatile addition to outdoor spaces, offering opportunities for entertainment and family bonding. Expert Tips for Setting Up a Fire Pit Tip 1: Selecting the Perfect Location There are no strict […]

Drive-In Style: Cruising Through the Ultimate Guide to Planning and Designing Your Dream Carport

A carport is more than just a shelter for your vehicle; it’s a valuable addition to your property that offers numerous benefits. From protecting your car from theft and the elements to adding value to your home, a well-designed carport can enhance both the aesthetics and functionality of your outdoor space. If you’re considering adding […]

What Is Wet Masonry?

Wet masonry work refers to the construction or repair of masonry structures using mortar that has a higher water content than usual. This method involves adding additional water to the mortar mix, which can make it easier to work with and manipulate during the construction process. However, it’s important to note that excessive water in […]

Can Sports Courts Be Installed In Residential Areas?

Yes, sports courts can certainly be installed in a residential setting, providing homeowners with opportunities for recreation, fitness, and entertainment right at home. Types of Sports Courts Suitable for Residential Areas Basketball Courts: A half or full-sized basketball court can be installed in a backyard or on a driveway, complete with a hoop, backboard, and […]

Pools and Drywells: The Insider Need to Know

A drywell, also known as a soakaway pit or an infiltration pit, is a subsurface structure designed to manage excess water runoff, particularly in areas where drainage may be challenging. In the context of a pool, a drywell serves several important purposes. The Vital Functions of a Drywell Water Management: A pool can generate significant […]

Is A Pool A Good Investment?

Whether a pool is a good investment depends on various factors such as your location, climate, personal preferences, and financial situation. Here are some considerations to help you determine if a pool is a good investment for you. Should You Invest in a Pool? Key Considerations Cost: Pools can be expensive to install, maintain, and […]

Asphalt: What’s It Made Of?

What’s The Difference Between HL3, HL3a, HL5 and HL8 Asphalts And What Are They Used For? Asphalt is a versatile material used in various construction projects, particularly in road construction. The terms HL5, HL8, HL3, and HL3a refer to different types or grades of asphalt mixtures commonly used in pavement construction. Here’s an explanation of […]

The Cost of DIY Asphalt Sealing vs. Hiring a Professional

Whether to DIY or professionally seal your asphalt driveway boils down to cost, time, and the quality of the end product. DIY asphalt sealing is less expensive initially, with the minimum materials such as sealant, crack filler, and tools ranging from $73 to $130 based on your driveway size. It does take 3-5 hours of […]

Make a Splash: Why Water Features Are the Coolest Addition to Your Yard

Yo, what’s up, fellow trendsetters? Today, we’re diving into one of the hottest backyard trends that’s making a huge splash – water features! From chill backyard vibes to jaw-dropping curb appeal, adding a water feature to your outdoor space is like injecting instant style and value. Today, we will be going through a few ways […]

The Big Question: Can I Skip the Landscape Designer?

So, you’re itching to transform your outdoor space – dreaming of a killer patio, a garden that’s Instagram-worthy, and you have the perfect construction team waiting for you, but the fear of the cost and the attitudes of Designers! You want to be the driver of the bus, but darn those Designers and their ways! […]

Enhancing Biodiversity: 10 Essential Plants for a Thriving Bird-Friendly Yard

Creating a bird-friendly yard goes beyond mere aesthetics; it’s about fostering a harmonious ecosystem where birds can thrive and contribute to the natural balance of your environment. By selecting the right plants, you can attract a diverse array of bird species, provide essential food sources, and create habitats that support nesting, roosting, and foraging activities. […]

Creating Your Dream Outdoor Kitchen: A Comprehensive Guide to Design and Functionality

Elevating your outdoor living space with a well-designed kitchen is a transformative experience. Outdoor kitchens offer a unique blend of convenience, comfort, and style, providing a hub for culinary creativity and outdoor entertainment. Whether you’re envisioning a sleek modern design or a rustic retreat, crafting your dream outdoor kitchen requires careful planning and attention to […]

Illuminate Your Deck: A Comprehensive Guide to Choosing the Perfect Lighting

Your deck is more than just an outdoor extension of your home; it’s a sanctuary for relaxation, entertainment, and connection with nature. And when the sun sets, the right lighting can transform your deck into a captivating and functional space. In this comprehensive guide, we’ll delve deeper into the world of deck lighting, exploring a […]

Finding the Perfect Placement: Considerations for Cabana Proximity to Pool and Interlocking

The allure of a cabana by the poolside is undeniable, offering a luxurious retreat for relaxation and entertainment. However, determining the optimal placement of your cabana in relation to your pool and interlocking requires careful consideration of several factors to ensure functionality, aesthetics, and safety. Cabana Placement Guide When deciding how close a cabana can […]

Essential Tools for Canadian Spring Gardening: A Beginner’s Guide

As the snow melts away and the warmth of spring envelops Canada, many aspiring gardeners eagerly anticipate the opportunity to cultivate their own green oasis. While the prospect of starting a garden may seem daunting to beginners, equipping oneself with the right tools can make the process much more manageable and enjoyable. Must-Have Gardening Tools […]

The Color Mystery of Hydrangeas: Exploring the Phenomenon of Pink and Blue Blooms

Hydrangeas are renowned for their stunning blooms, but what intrigues many gardeners is the fascinating phenomenon of their color-changing flowers. While some hydrangeas boast vibrant pink blooms, others flaunt striking shades of blue. The secret behind this color variation lies in the intricate interplay between soil acidity, aluminum availability, and hydrangea genetics. How Soil pH […]

Understanding Why Spruce Trees Leak Sap and How to Deal with Car Damage

Spruce trees, with their majestic presence and evergreen foliage, are beloved additions to landscapes. However, for some unlucky car owners, parked beneath a spruce tree can lead to an unexpected and frustrating problem: sap dripping onto their vehicles. Let’s explore why spruce trees leak sap and how to mitigate the damage to your car. Understanding […]

Why Asphalt Driveways Need Regular Maintenance and Sealing

Asphalt driveways are durable and great-looking, but they need regular maintenance and sealing to stay in top shape. Sealing protects your driveway from weather damage, prevents cracks and potholes, and helps resist oil and chemical spills. It also keeps your driveway looking fresh and polished, improving your home’s curb appeal. Plus, regular sealing is a […]

Exploring the Relationship Between Saunas and Weight Loss

Saunas have long been revered for their relaxation and detoxification benefits, but can they also aid in weight loss? While saunas are not a direct solution for shedding pounds, they can complement a healthy lifestyle and contribute to overall weight management in several ways. How Saunas Enhance a Healthy Lifestyle Firstly, saunas induce sweating, which […]

Elevate Your Landscape Design with Ontario’s Finest Grasses: Low Maintenance Appeal

In the realm of landscape design, Ontario’s native grasses stand as versatile and visually captivating elements that bring texture, movement, and beauty to outdoor spaces. From urban gardens to rural landscapes, these grasses offer both aesthetic appeal and practical benefits for designers and homeowners alike. Let’s explore some of Ontario’s best architectural grasses renowned for […]

How Often Should You Seal Your Asphalt Driveway?

Sealing your asphalt driveway is a great way to improve its appearance and keep it in good condition for years to come. However, one of the most common questions homeowners ask is, “How often should I seal my driveway?” Well, you have to consider a few things, like how bad the weather gets and the […]

The Allure of Focal Point Trees: Elevating Garden Aesthetics with Stunning Presence

In the realm of garden design, focal point trees stand as majestic sentinels, captivating attention and infusing landscapes with unparalleled beauty. These towering specimens not only serve as visual anchors but also evoke a sense of grandeur and harmony within the garden. Let’s explore what makes a focal point tree so stunning and why it’s […]

Ontario’s Botanical Bounty: Adding Local Flora to Summer Cocktails

As the warm breeze of summer sweeps across Ontario, it brings with it an abundance of native plants that can elevate your cocktail game to new heights. From refreshing mint to zesty citrus, Ontario’s diverse botanical landscape offers a myriad of flavors and aromas to experiment with Indigenous Plants to Enhance Your Summer Cocktails Wild […]

Customizing Your Irrigation System: Matching Plant and Soil Types for Optimal Watering

An irrigation system tailored to the specific needs of your plants and soil types can make a significant difference in the health and vitality of your landscape. While many standard irrigation systems offer general watering schedules, customizing your system based on plant and soil types allows for more efficient water use and better overall plant […]

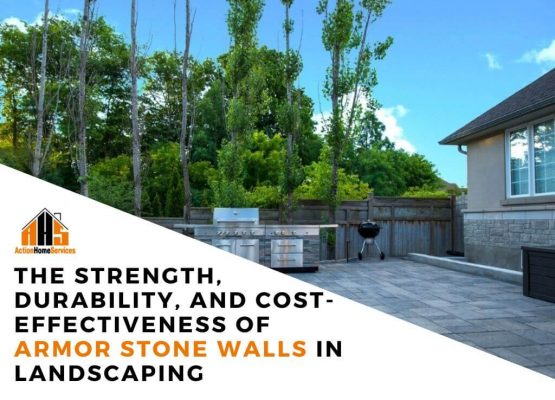

The Strength, Durability, and Cost-effectiveness of Armor Stone Walls in Landscaping

Armor stone walls stand out as one of the most robust, durable, and cost-effective solutions in landscape design. Their popularity stems from several key factors that make them an ideal choice for various landscaping applications. Exploring the Resilience and Value of Armor Stone Walls Firstly, the inherent strength of armor stone makes it an exceptional […]

Does Your Contractor Need a Background Check?

When it comes to hiring a contractor for your home improvement projects, ensuring your peace of mind and the safety of your property should be paramount. While it may seem like an unnecessary step, conducting a background check on your contractor can save you from potential headaches down the line. Let’s delve into why this […]

What is Winterscaping?

In the context of landscaping, winterscaping refers to the activities or design considerations specifically tailored for the winter season. As Canadians we endure lengthy winters, through winterscaping applications including garden planning with winter green planting, showcasing alleys and framing the backdrop, we can create winter-friendly outdoor spaces. This even applies when planning for snow and […]

How does an Irrigation System Work?

An irrigation system is a method of delivering water to plants or crops to help them grow. There are various types of irrigation systems, each with its own features and advantages. A Comprehensive Overview of Irrigation Systems Water Source: The system starts with a water source, which could be a municipal water supply, well, pond, […]

Navigating the Turf: Grass Seed vs. Sod – Decisions, Dilemmas, and Dazzling Lawns!

The pride associated with homeownership extends beyond the walls of your house, into the expansive green canvas of your lawn. Whether you’re rejuvenating an existing lawn or starting from scratch with bare soil, the critical decision between grass seed and sod plays a pivotal role in achieving the lush, vibrant lawn you envision. This article […]

Brightening Your Security: How Landscape Lighting Can Safeguard Your Property

In the ever-evolving landscape of home security, one element that often flies under the radar is installing landscape lighting. Beyond its aesthetic contributions, well-planned illumination can play a vital role in safeguarding your residential property. Unveiling the Benefits of Landscape Lighting In this comprehensive guide, we’ll explore the multifaceted ways in which landscape lighting can […]

How to Protect the Surroundings When Sealing Your Driveway

One of the biggest things that’s overlooked when you try to do your own driveway sealing job, is how to protect its surroundings. Luckily, here are some tips on how to properly protect the driveway surroundings when sealing. Start by using good-quality painter’s tape, since cheap tape peels off a lot easier and that’ll make […]

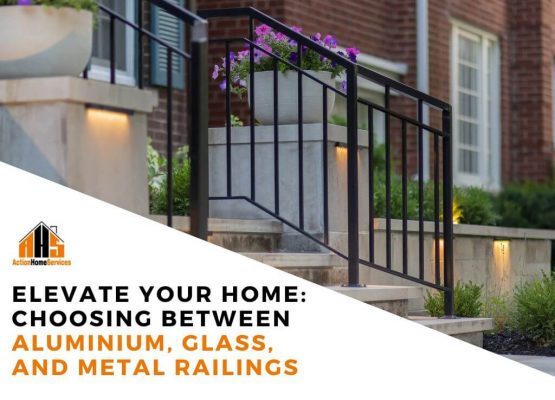

Elevate Your Home: Choosing Between Aluminium, Glass, and Metal Railings

When it comes to transforming your home’s exterior, the choice of railings plays a pivotal role, blending safety with aesthetics to create a harmonious living space. In this exploration, we delve into the world of three distinct railing materials – Aluminium, Glass, and Metal. Each offers a unique blend of style, durability, and functionality, promising […]

Action Home Grilling: Salmon with Green Romesco Salsa

Ingredients: Vegetable oil 1 2¾–3-lb. whole skin-on side salmon 1–2 Tbsp. plus ⅓ cup extra-virgin olive oil, plus more for drizzling Kosher salt 1 large jalapeño, ribs and seeds removed, finely chopped 3 garlic cloves, finely grated 1 cup coarsely chopped parsley ¾ cup coarsely chopped unsalted roasted almonds ¼ cup fresh lemon juice ½ […]

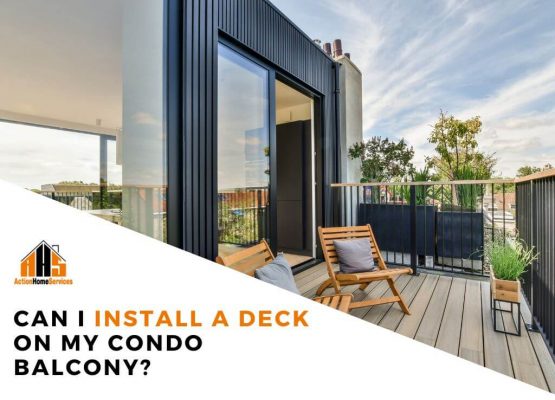

Can I Install A Deck On My Condo Balcony?

The ability to install a deck on your condo balcony depends on several factors, including local building codes, condo association rules, and the structural capacity of your balcony. Here are some considerations: Condo Association Rules: Condo associations typically have rules and guidelines regarding modifications to individual units, including balconies. Check with your condo association to […]

12 Accessibility Features for Your Pool

Creating an accessible pool environment is essential to ensure that individuals with varying abilities can enjoy the pool safely. 12 Features to Consider for Your Pool Here are 12 accessibility features that can be added to a pool Zero-Entry or Beach Entry: A gradual slope at one end of the pool provides a gentle entry […]

Deck Dreams Unleashed: Navigating Permits in GTA with Action Home Services as Your MVP

Picture this: your backyard, transformed into a VIP oasis with a deck that’s the talk of the town. But before the confetti cannons pop, securing a deck permit becomes a critical scene in this backyard blockbuster. In this guide, we’ll not only explore the “when” of building permits but also dive into the cons of […]

Stepping Stones: Paving the Way to Aesthetic Harmony in Landscape Design

Howdy, fellow landscape enthusiasts! Today, we’re putting on our cowboy boots and stepping into the world of design, where the humble stepping stone takes center stage. If you’re looking to spruce up your outdoor space, consider these rustic gems as your trusty sidekick in creating a visually stunning and practical landscape. 1. A Symphony of […]

Top 5 Landscape Design Mistakes!

Landscape Design Pitfalls to Avoid 1. PUTTING THE PLANTS ONLY ON THE FENCE LINE: This is a common design method for homeowner to use, that they can maximize their inner patio space and to soften the fence line. Ironically, this actually makes the space smaller! The garden will then further make the space seem smaller, […]

What Is A Plunge Pool And How Do They Differ From A Hot Tub?

When it comes to creating an oasis of relaxation in your backyard, the choice between a plunge pool and a hot tub can significantly impact your overall experience. These two compact water features may seem similar at first glance, but their purposes, temperatures, and designs diverge in ways that cater to different preferences and needs. […]

Can I Add Dimmers to My Outdoor Lighting?

Yes, you can add dimmers to your landscape lighting to control the brightness and create different lighting effects. Dimmers are devices that allow you to adjust the intensity of the light output. Here are some steps you can follow to add dimmers to your landscape lighting. A Guide to Adding Dimmers 1. Check Compatibility: Ensure […]

5 Things to Avoid When Sealing Your Driveway

One of the best ways to upgrade both the looks and durability of your driveway, is to get it sealed. But if you want good results then you have to make sure you avoid these mistakes when sealing your driveway. First, avoid cheap water-based sealants, they don’t offer the durability asphalt needs. Make sure you […]

Car Theft Prevention in the Landscape

You heard me and you would be SURPRISED if you understood how many design clients come through our office with this request! Action home services can help! If you are reading this article it is likely that this is something you are considering for your home anyways so let us provide you with some creative […]

Splish, Splash, Sweat: The Health Benefits and Splash-tastic Workouts of a Swim Spa

Dive into the world of wellness with a swim spa – the hybrid haven of relaxation and fitness that’s making waves in the health scene. Beyond its bubbling waters and soothing jets, the swim spa brings a tidal wave of health benefits, making it more than just a glorified hot tub. Buoyant Bliss: One of […]

A Nose for Neighborly Nudges: Keeping it Fresh by the Pool

Picture this: I’m all set to indulge in some serious poolside bliss in my new backyard. The sun’s doing its thing, the water’s shimmering like a million diamonds, and I’m ready to dive into the sweet symphony of relaxation. But hold up, there’s an unexpected guest crashing this pool party—my neighbor’s not-so-fragrant potpourri of weed […]

Can I Install An Ice Rink In My Backyard?

Creating an ice rink in your backyard can be a fun and exciting project, especially if you enjoy winter sports like ice skating or hockey. It’s an excellent opportunity to transform your outdoor space into a versatile, year-round entertainment venue! An at-home ice rink encourages physical activity, fostering health and active lifestyles for individuals of […]

What Is Better, Hot Tub Or A Swim Spa

Alright, buckle up, folks, because we’re about to unravel the epic tale of hot tubs and swim spas – two aquatic dynamos that might look similar at first glance, but are as different as surfboards and snowboards in the grand adventure of aquatic leisure. Distinguishing Between Hot Tubs and Swim Spas Let’s start with the […]

What Are The Benefits Of Power Washing?

Power washing, also known as pressure washing, involves using a high-pressure water spray to clean surfaces. It offers several benefits in various applications. The Multifaceted Benefits of Power Washing Efficient Cleaning: Power washing is highly effective in removing dirt, grime, mold, mildew, and other contaminants from surfaces. The high-pressure water stream can quickly clean large […]

Are Swim Spas High Maintenance?

Swim spas, like any other type of pool or hot tub, require regular maintenance to ensure they remain in good condition and provide safe and enjoyable experiences. The level of maintenance for a swim spa can depend on various factors, including its size, features, usage, and the local environment. Exploring Essential General Considerations Filtration System: […]

Functional or Pure Folly?

The Constant Struggle One of the biggest struggles that design faces is how to make me more excited but still keep it rather true to the original intent, and budget. Functional design refers to the process of creating a product or system with a focus on how well it meets its intended purpose or function. […]

Why Are Swim Spas the Next Cool Thing?!

Alright, gather ’round, water enthusiasts and chill seekers – let’s dive into the cosmic coolness of swim spas, the aquatic marvels that are basically the rock stars of backyard relaxation! Picture this: the perfect fusion of a pool and a spa, a hybrid haven where the cool meets the cozy, and your aquatic dreams take […]

The Difference Between Oil-Based and Water-Based Sealants

There’s a lot that goes into sealing your driveway, and picking the right sealant is your first step. You have to make sure you know the difference between an oil-based sealer and a water based one. Oil-based driveway sealing is more common since they are generally the better sealer for long term. They last longer […]

The Future of Outdoor Living

With many great innovative products getting thrown at us on a daily basis, almost as if they are trying to test everything out and hope something will stick! What are the tried and true products that you should be keeping your eyes on for the upcoming future trends?? Here are a few tried and true […]

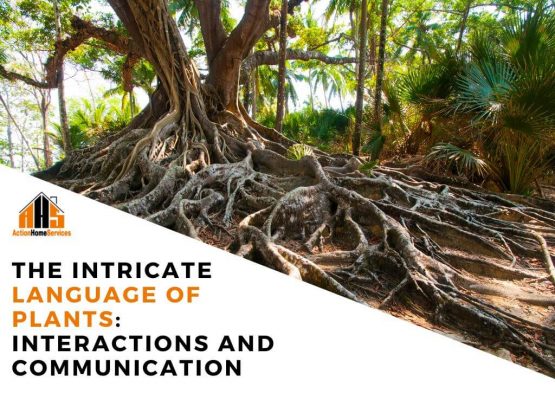

The Intricate Language of Plants: Interactions and Communication

Plants, though seemingly silent and stationary, engage in a sophisticated form of communication with one another. Although it isn’t as exciting as we see in Lord of the Rings, their methods are a lot more subtle, soft, unheard, unseen, and very, underground. The method that plants speak to one another mostly involves a variety of […]

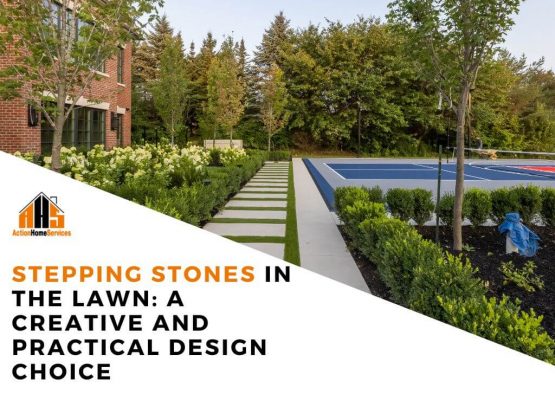

Stepping Stones in the Lawn: A Creative and Practical Design Choice

The artful integration of stepping stones into a lawn is a design choice that not only adds aesthetic appeal but also brings a multitude of practical benefits to outdoor spaces. From enhancing the visual interest of the landscape to providing functional pathways, stepping stones contribute to a well-designed and dynamic garden environment. Visual Aesthetics One […]

How To Increase The Appeal Of Your Property On A Budget

The Why? Let’s Bring Some High-value Changes On A Low Budget! Did you just move into an older property? Have you been neglecting your home for a while? Recently got inspired?? Here are a few ways to boost your property value! Many go through the same steps as listed below, and they decide to take […]

The Benefits of Having a Pool

Having a pool on your property can offer several benefits, both in terms of personal enjoyment and potential property value. Advantages of Having a Pool and its Property Enhancement Here are some advantages of having a pool and how it can add value to your property: 1. Recreation and Relaxation: A pool provides a private […]

Can A.I Replace Designers?

A.I is an absolute powerhouse when it comes to pumping out fantastic conceptual rendering in seconds! With a few prompt words and a few tweaks, anyone can produce an illustration that’ll take human artists hours, or even days to come up with! With all their light-speed processing speed, the entire world’s wealth of data, and […]

What Are The Primary Benefits Of Having A Heated Driveway?

A heated driveway, typically equipped with a radiant heating system, offers several benefits, especially in regions with cold climates or frequent snowfall. Here are some primary advantages: Snow and Ice Removal: The most obvious benefit is the ability to melt snow and ice on the driveway. This eliminates the need for manual shoveling or plowing, […]

What Types Of Fire Features Are Available?

There are various styles of fire features available on the market. These features can include outdoor fireplaces, fire pits, fire tables, and other outdoor heating elements. The specific styles and designs may vary based on current trends, technological advancements, and consumer preferences. Some common styles of fire features include: 1. Traditional Fireplaces: A traditional fireplace […]

Making The Most Of Accessible Design

Embarking on the journey of creating an accessible landscape for your home is all about turning common concerns into exciting opportunities. Think uneven surfaces, tight spots, and signs playing hide-and-seek – challenges that are just waiting for a creative makeover. Now, we get it – making these changes can have you checking your pocketbook. But […]

How To Choose Your Pool and/or Landscape Contractor

1. Check their reviews Whether you are accessing reviews via platforms such as Homestars or Google, it is imperative to ascertain the company’s longevity. It is advisable to trace their review history back to the earliest entries, observing the timeliness and responsiveness of the company in addressing reviews and resolving issues. This serves as a […]

5 Benefits of Hiring a Landscape Designer

5 Key Benefits of hiring a landscape designer Hiring a landscape designer can offer numerous benefits, especially if you’re looking to enhance the aesthetic appeal and functionality of your outdoor space. Here are some advantages of hiring a landscape designer: Expertise and Creativity: Landscape designers are trained professionals with expertise in horticulture, design principles, and […]

Why cold plunges are the hottest newest addition to outdoor living

Growing popularity: In recent years, the growing popularity of cold plunges has become a testament to the increasing interest in holistic wellness practices. Once considered an extreme pursuit, cold plunges, or ice baths, have transitioned from niche fitness communities to mainstream health and wellness routines. Advocates of cold exposure emphasize its numerous benefits, ranging from […]

2023 WRAP UP

Design Trends: 2023 trends have started to change, COVID has given everyone, clients and suppliers, a different outlook on the landscape community as whole. We are seeing a shift in trends this year leaning toward greener industries and placing more emphasis on the human connection with nature. This is creating an increase in people wanting […]

Do You Need A Permit To Build A New Deck?

Building a new deck is an exciting endeavour that can transform your outdoor space, providing a space for entertainment, and relaxation, while enhancing your home’s appeal. However, amongst the planning and envisioning, there’s an important aspect that homeowners must not overlook – obtaining the necessary decking permits. While many factors influence the deck construction process, […]

Exterior Saunas: More than just leisure

1.Health Benefits and Wellness: Saunas have been used for centuries across various cultures for their therapeutic and health-promoting benefits. These heated rooms, typically maintained at temperatures between 150 and 195 degrees Fahrenheit, offer a range of physical and mental advantages. One of the primary health benefits of saunas is their ability to promote cardiovascular health. […]

Factors That Can Affect The Cost Of Your New Deck

Building a new deck at your residence is a wonderful addition to any outdoor space, offering versatile opportunities for entertainment, dining, relaxation, and enhancing the overall appeal of your home. However, the cost of building a deck can vary due to several factors that influence pricing. Understanding these factors is crucial to making informed decisions […]

What Is The Best Type Of Wood For Your New Deck?

When envisioning the perfect outdoor deck for your home, choosing the right type of wood is crucial. Twp popular choices in Canada often stand out in the realm of wooden decks, pressure-treated wood and cedar. Each comes with its own set of unique properties, benefits, and limitations that cater to various preferences and considerations. Learn […]

How Do You Prepare Your Pool For Winter? Get 7 Key Tips Here

Winterizing your pool is essential to ensure its longevity and usability. Canadians know the harshness of the winter season, and to combat freezing temperatures, snow, and debris accumulation, you need to prepare your pool for the season. Winter pool maintenance can be a daunting task, but with our pool winterization guide, you can learn how […]

Are Heated Driveways Worth It?

As the winter chill descends on Canada, homeowners face the familiar challenge of clearing snow and ice from their driveways. Shoveling, plowing, and salting can be not only physically demanding but also time-consuming. This is where heated driveways step in as a modern solution, offering convenience and safety during the harsh winter months. What Are […]

When Is The Best Time To Do Landscaping?

The Answer Depends On Who You’re Asking. As landscape designers and contractors, our perspective on incorporating flowers, shrubs, and trees into our landscape designs may differ from that of your local garden center. While they might emphasize the prime months for planting, such as April and May after the frost, they may also suggest the […]

Why Get a Salt Water Pool – Top Pros & Cons of Saltwater Pools | Chlorinated Pools

Outline Introduction What is a Salt Water Pool? Benefits of Salt Water Pools Salt Water Pool Maintenance Cost Considerations Health Benefits of Salt Water Pools Conclusion FAQs Why Get a Salt Water Pool Introduction Are you considering installing a pool in your backyard? If so, you may want to explore the benefits of a […]

Fiberglass Pool Showdown: Assessing the Best Pool Options for Your Home

Understanding Fiberglass Pools Dipping into the realm of home improvements and renovations, adding a swimming pool to your home is a significant decision. If you’re considering this addition, fiberglass pools might be on your radar. These pre-made shells are delivered in one piece and installed into your yard—a pretty straightforward process. However, the simplicity of […]

Chlorine vs. Saltwater Pools

Which should you choose? Firstly, it’s essential to clear up a common misunderstanding; you’re not choosing between a chlorine pool and a saltwater pool. Both types of pools use chlorine to create a safe swimming environment. Both types of pools have salt. In saltwater pools, the taste of salt may overpower the taste of chlorine, […]

Pools Are a Great Investment, But Not for the Reason You’d Think

Installing a pool is an investment in fun. It enhances your outdoor lifestyle. It creates a great place to exercise, relax, entertain, and for your kids to play. It may increase the value of your home, but it may not. George Klump, an experienced real estate agent at Royal LePage, suggests that having a pool […]

Pool Landscaping Isn’t Just About Aesthetics

Pool landscaping isn’t just about aesthetics. When your pool’s drainage is working, no one gives it a second thought, but when it fails, it becomes very apparent. At the very least, it can cause unsightliness and inconvenience; at its worst, it can cause damage that is costly to fix. For this reason, taking a careful […]

Everything You Need to Know About Fiberglass Pools

When we meet with a potential pool-buying customer, we discuss their ideal outdoor lifestyle, the outdoor space they envision, and their budget. By understanding their goals and constraints, our team will design a custom outdoor space that fits their parameters. We don’t come in with preconceived ideas. One of the three types of in-ground pools […]

Should You Reseal Your Interlocking Driveway and Patio?

Benefits of Resealing Your Interlocking If you have an interlocking stone driveway, patio, walkway, or pool deck, you’ve invested in your property and care about how it looks. It’s a good choice because, although interlocking stones and pavers cost a little bit more upfront, they are easier and less expensive to maintain over time. But, […]

Pool Experts: 10 Common Pool Maintenance Mistakes to Avoid

Not all pool owners are experts when it comes to maintaining their pools and that’s ok! If you’re one of these people, then take a look at the 10 points below to make sure that you’re not making any common mistakes with your own personal pool. We’ll walk through 10 important steps toward keeping your […]

How to Remove Oil from Your Interlock

The winter will soon be over, and the snow and ice will finally melt from your interlocking paver driveway. All winter long, if you’ve even looked at your driveway, your thoughts have been about shoveling or de-icing and certainly not about the stains that may lie underneath. But, when spring arrives, you start to look […]

Building Permits: Necessary Evil or Blessing in Disguise?

If you search Google for construction failures, it doesn’t take long to find stories about collapsed-building events. In almost every case, the causes listed include poor construction practices, poor project management, structural issues, or faulty materials. Municipalities react to these disasters by requiring licenses from their contractors and tradespeople and amending their building code to […]

How To Maintain Your Artificial Turf

Table of Contents What Is Artificial Turf? The Technology Behind Artificial Turf and Fake Grass Everything You Need To Get Started Artificial Turf Requires Periodic Cleaning To Keep It Looking The Greenest Many Other Things Can Tarnish and Ruin Artificial Grass Pets and Artificial Turf How to Clean Deep Stains In Your Artificial Turf Prevent […]

How to Approach Functional Landscape Design

Table of Contents Backyard Basics The Landscape Design Process Landscape Site Survey Design Planning & Considerations Permits Construction Final Touches Summary Backyard Basics It’s never too early to start planning your outdoor summer “staycation”. Regardless of the size or shape of your outdoor space, when it comes to creating a functional landscape design, the possibilities […]

How Adding A Deck To Your Backyard Increases Your Home’s Value

A lot of homeowners in recent years are taking advantage of a trend that’s increasing in popularity – they are making the decision to add a deck to their backyard. Not only does this provide them with a great space for entertaining guests and hosting BBQs, but it also adds value to their home. If […]

Best Of Homestars For 6 Years! A Thank You From Our Team!

We are so so happy to announce that we have won Homestars’ Best Of Award for 6 years now. In the home improvement industry, the Best Of Award is given by Homestars as a recognition of companies that demonstrate “consistency, professional integrity, and unparalleled customer service.” Our team had to undergo a rigorous vetting process […]

The Environmental Benefits of Interlocking Your Driveway

If you’re a homeowner, you may be considering interlocking your driveway as a way to boost your curb appeal. Interlocking is a type of paving that uses small stones or bricks to create a pattern that has become increasingly popular amongst homeowners in recent years. It’s a popular choice for driveways because it’s durable, easy […]

Choose the Right Type of Interlocking Stone For You

There are many different types of stone that can be used for interlocking design projects. The most common type of stone is granite, which is a very strong and durable material. Other popular choices for interlocking driveways include limestone, sandstone, and slate. Different Types Of Stone Granite is one of the most popular choices […]

Do I Require a Permit to Widen My Driveway?

The Greater Toronto Area is a fast-growing, extremely populated city. This means that space, whether it be for roads, businesses, parks or homes, urban space is highly limited and sought after. This means that neighbours normally live side by side in densely populated centers, even if it is a single-family home. Driveway Permit A lot […]

Why You Should Choose Interlocking Pavers and a Heated Driveway

As you drive up to your home, the first thing you see is your driveway. Make a great first impression with a beautiful driveway made of interlocking pavers. Interlocking pavers are a great way to create a durable and attractive surface for your driveway that will last for years to come. What are Interlocking Pavers? […]

The Difference Between Asphalt Paving and Asphalt Sealcoating

Have you ever looked into getting your asphalt driveway done, found asphalt paving and asphalt sealcoating services, and was confused about the difference between the two? Don’t worry, you’re not the only one. Many customers are unsure about the difference between the two. Well, we can help with that. As asphalt experts serving Toronto and […]

We Now Offer Swimming Pool and Hot Tub Services

Located in Toronto, we are a construction company that offers the best services possible. We provide services such as stone work, wood work, paving, and landscaping. However, now we offer more! We are now providing swimming pool and hot tub services to Toronto and the GTA. Want to learn more about our new services? Then […]

Bins Toronto: A New Service From AHS

Here at Action Home Services, we strive to accommodate our Toronto and Greater Toronto Area customers to the best of our ability. As such we are proud to present Bins Toronto – the perfect service for anyone embarking on a renovation or construction project this year. What is Bins Toronto? While we offer a number […]

5 Tips For Designing The Perfect Backyard

A house is not home without a beautiful backyard. Not only do you want to impress guests whenever they visit, but you also want to feel proud when you spend time outside with your family. There is nothing better than enjoying a few hours in a perfectly-groomed garden. Here are some essential tips to help […]

Residential Driveway Sealing: The Best Time To Do It

Your residential driveway isn’t just a convenient space to park your car, nor is it simply an opportunity to enhance your curb appeal. Whether you have asphalt, concrete or interlocking pavers sprawled across your driveway – each type could benefit from residential driveway sealing. Before going any further, it is important to mention that you […]

We Have An In-House Designer!

Here at Action Home Services, we are always looking for ways to improve our service for our customers. Whether they are a residential or commercial client, we want any customer to feel like we are going above and beyond to help them enhance their property. We understand the important role that landscaping can play in […]

Landscaping Toronto: Winter Landscaping Ideas

Just because the leaves have fallen and the ground is covered in frosty white snow that doesn’t mean the space around your property should be disregarded until the next season. Landscape upkeep may not be easy, or even practical, during the winter months. This does not mean you can’t prepare to leave your yard […]

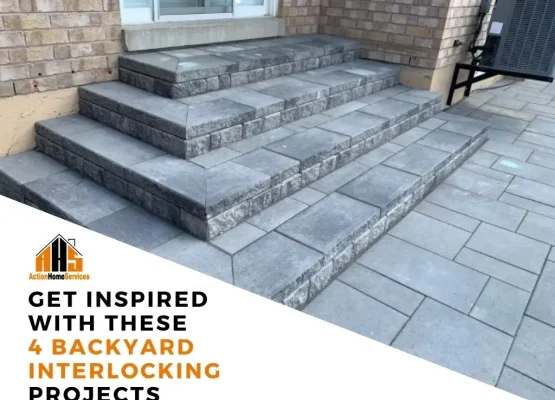

Get Inspired With These 4 Backyard Interlocking Projects

Interlocking pavers enhance the property in multiple ways. For starters, they allow you to minimize landscaping efforts, which results in a low-maintenance backyard. Moreover, they are weather-resistant, safe to use, durable enough to stand the test of time and allow you to create unique styles. Here at Action Home Services, our team specializes in backyard […]

Landscaping Toronto: Cool Features For Your Home

When people think about landscaping, the first thing that comes to mind is their yard. It’s only natural when landscaping is defined as a process that helps to make a yard or some piece of land more attractive by altering the existing design. While you can most certainly switch it up or create new aesthetics […]

Landscaping Toronto: Avoid These 6 Landscaping Mistakes

Landscaping is not only about maintaining the lawn. It also involves the trimming of your bushes, planting more trees and flowers, installing new additions like a stone path or a patio to the space, and much more. At the end of the day, it’s all about the aesthetics. Landscaping is transformative, and it’s a wonderful […]

Why You Need Commercial Asphalt Sealing for your Property

Asphalt is one of the most popular paving materials for several reasons. It is most often used in commercial settings like parking lots and driveways as well as roads due to its durable nature. If properly cared for, asphalt can last as long as 30 years before repairs are needed. If you are a property […]

4 Ways to Make Your Interlocking Look Unique

Interlocking pavers are a popular choice to create beautiful outdoor areas around your property. From driveways, walkways, to patios and the lot – these pavers are transformative in nature. Their versatility allows you to use them in a plethora of spaces such as fire pits, pool decks, as well as retaining walls. In fact, pavers […]

Signs You Need an Interlock Repair Service

Interlocking concrete pavers are an excellent way to enhance your home’s curb appeal. Not only are they customizable, they are a low maintenance and cost-efficient alternative – at least when compared to other materials such as gravel and poured concrete. In addition, they are perhaps one of the most durable options to install on your […]

Interlocking Pavers vs. Other Materials

Interlocking is an ideal solution for your driveways and walkways, as well as courtyards, for a number of reasons. Particularly because they hold several advantages over other materials such as gravel and poured concrete. That is not to say the other materials aren’t good options. They all have their own merit, but concrete pavers simply […]

Showcasing 5 of Our Interlocking Projects

Over the years, we have completed many fantastic projects. Our experience has allowed us to work with many clients on a diverse range of projects. Whether it is our work with landscaping, driveway installation, interlocking, or adding an addition to a property, we always deliver beautiful and memorable results. Because we are so proud of […]

Asphalt Sealing: What Makes Our Asphalt Sealant the Best

If you own a property, whether it is your business or your home, you want it to be welcoming and attractive. However, as time passes, your asphalt driveway will begin to deteriorate due to wear to tear. Whether its cracks, potholes or any other damage that is caused by traffic or water, there is a […]

The Definitive Landscaping Toronto Guide to Growing Greener Grass

Having a healthy, beautiful landscape is the want of just about any homeowner. Having great hedges, a garden, or any other landscape feature will improve the look of your yard. But if you don’t have green grass, every other feature will be a waste. Yellowing grass can bring down the curb appeal of a […]

The 4 Most Durable Stones for Interlocking Toronto Projects

Interlocking is a great way to turn your home into a piece of art. The natural beauty of stone strategically placed, whether for a path or addition to your home, will bring an air of elegance to the entire property. There are many different types of stones that can be used for interlocking, each having […]

Common Asphalt Problems

Over time, asphalt can start to develop issues that can be as small as a slight crack to as big as a large indentation that runs through the entire surface. There are numerous issues you can face when you have asphalt installed on your property with, luckily, equally as many fixes. Throughout this article, we […]

What is a Permeable Driveway?

Concrete is seen as the standard for homes. Patios, steps, walkways and especially driveways are mainly constructed using concrete. While concrete is strong and will last for some time, there are many flaws that accompany it. One of the biggest being concrete’s inability to allow water to soak back into the ground which can cause […]

The Importance of Asphalt Sealing for your Driveway

When picking between asphalt and concrete homeowners tend to go with asphalt due to it having a lower price while still providing durability comparable concrete. Although, in order for asphalt to provide your property with great support, you have to first have a seal correctly applied during the installation process. Only after the seal is […]

Can Interlocking Increase the Value of My Home?

Interlocking pavers are commonly constructed with cement or concrete with the purpose of emulating the effects of cobblestone. There are many uses for interlocking pavers such as driveways, steps, pathways, patios and more. Interlocking can be installed easily without mortar, making for easy self-installation. Interlocking pavers are connected using sand and can be an alternative […]

The Benefits of an Interlocking Patio

Thinking about installing an interlocking patio in your backyard? Of course you are! Why else would you be here on this blog if you weren’t thinking about going with pavers for your backyard? And we gotta say, you are making a good choice for your home. After reading that, you’re probably thinking to yourself, “Well, […]

What Factors Into Driveway Sealing Price in Toronto?

If you have a driveway or parking lot made of asphalt, then you most likely chose that material because it is easy to install, is very durable, is relatively easy to maintain, and is fairly easy to repair if anything happens to your driveway. Although asphalt is a dependable material, it will be negatively impacted […]

What Factors Into Interlocking Price in Toronto?

When it comes to your home, exterior design can go a long way towards improving the overall aesthetic and the curb appeal of your home. Beyond that, it can make you feel really good about your home, and that’s because good exterior design can make your home look spectacular. Whether it is with plants, walkways, […]

Tips to Hire a Power Washing Company in GTA

With time, there are many conditions that your home goes through. Due to changes in weather and regular usage, the home gets dirty and requires maintenance over time. Dirt, grease, grime, and mold form on roofs, decks, and the concrete of your house. Hiring a pressure or power washing company is the best way to […]